Happy Easter! We will be closed for the Easter long weekend Friday 18 - Monday 21 April.

Saferoads customer Ventia required 300 metres of Separation Kerb on a project at Biggera Waters in Queensland. A small length of the separation kerb was to be installed over a bridge, in which an alternative to drilling holes was required to avoid damaging the bridge surface. Therefore, an alternative fastening method needed to be considered.

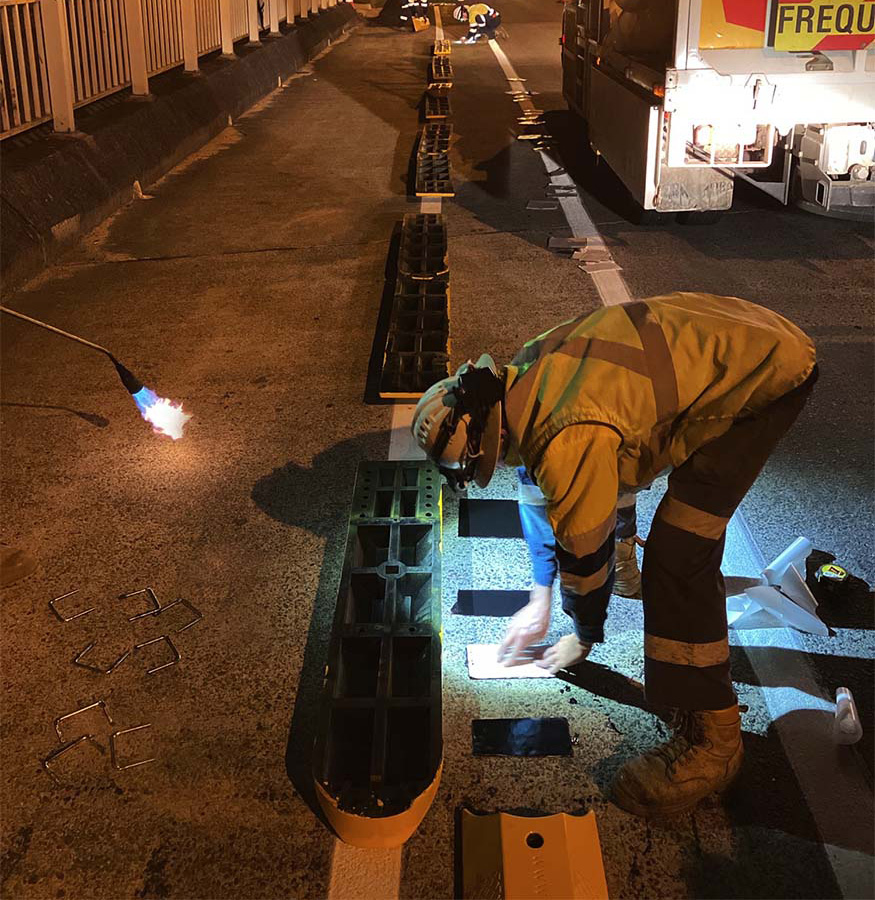

Saferoads had previously installed a similar rubber traffic control product to the ground using butyl adhesive pads. The Butyl adhesive pads provided a quick and easy way to permanently adhere the rubber base of the Separation Kerb to the bridge’s concrete and asphalt surface making it the perfect solution for this project. The butyl pads remain permanently flexible, helping to prevent the Separation Kerb from breaking away from the surface when an impact occurs.

In addition to this, the flexible design of Separation Kerb allowed short lengths (2.66m) of male and female sloped end pieces to be installed to both surfaces. This allowed water to drain through the system in between the gaps between the short installed lengths, ensuring an economically viable.

Separation Kerb is ideal for redirecting traffic and can be fitted with flexible delineation posts. This was imperative to allow variation in post placement to ensure that, in critical areas, vehicles were kept in their lane.

Saferoads specified the position of the Butyl Pads and installation specifications, which allowed the Separation Kerb to be successfully installed by Ventia. The result almost a year on sees the solution being highlighted as a real success story and very effective delineation between cyclists and motorists

“The Butyl Pads and the separation kerbs are still intact, and there have been no damages or issues. We are impressed with the product”

Ritvej Machchhar – Site Engineer, Ventia